Ceramics are non-metallic, inorganic materials noted for their wear/corrosion resistance, thermal stability, strength and good electrical insulation. Traditional and advanced ceramic products are available in a variety of shapes, sizes, forms and are produced with different ingredients/processing techniques. Master Bond adhesives provide engineers a range of viable design options and have been successfully employed for ceramic to ceramic and ceramic to dissimilar substrate bonding applications. Multiple select formulations have been engineered for adhesion to ceramic components containing aluminum oxide, zirconium dioxide, boron carbide, tungsten carbide, silicon nitride and other advanced technical ceramics.

Diverse ceramic materials have become essential in providing high performance, reliability, durability, longevity for key components used in the aerospace, automotive, electronic, communication, electrical and medical device industries. This has facilitated their use in fiber optics, microelectronic packaging, vibration sensors, microwave transducers, ferroelectric components, fuel cells, naval vehicles and sensors. Manually/automatically applied Master Bond polymeric joining compositions have enabled manufacturers to satisfy their adhesive needs for adhering ceramic surfaces even upon exposure to a combination of hostile conditions. This includes rapid heating/cooling, abrasion, chemical attack, high humidity, stress, fatigue.

Surface preparation for ceramic substrates

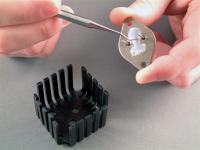

Even though ceramic substrates have high surface energy and can be easily wet, it is important to carry out the necessary surface preparation in order to optimize adhesion to different substrates. Typically, degreasing the substrates would help improve their bond strength. However, depending on the ultimate strength required, mechanical abrasion can also be carried out using emery paper or sand blasting. A combination of cleaning and mechanical abrasion can also be employed for optimum results.

Products for Bonding Ceramic Substrates

|

Supreme 11AOHT Thermally conductive, electrically insulative epoxy adhesive. Meets MIL-STD-883J Section 3.5.2 for thermal stability. High peel and shear strength properties. Non-drip system. Resists -112°F to +400°F. Toughened system. Can withstand rigorous thermal cycling. Convenient one to one mix ratio by weight or volume. Cures at room temperature. |

|

Supreme 10AOHT One part, oven cured epoxy system with excellent thermal conductivity and superb resistance to thermal cycling. Primarily used for bonding of heat sinks and sensors where heat transfer is desirable. Serviceable from 4k to +400°F. Convenient processing. |

|

EP31 Ultra high strength, two part epoxy adhesive that bonds well to most metals and plastics. Aluminum to aluminum lap shear strength exceeds 4,000 psi. T-peel strength >50 pli. Ambient temperature curing. Tough and resilient bonds. Combines low viscosity and optical clarity. Serviceable from -60°F to +250°F. Chemical resistant. First class electrical insulator. |

|

EP13 One component, heat curable epoxy adhesive. Serviceable from -60°F to +500°F. Paste viscosity. High tensile shear and compressive strength. Chemical resistant. Machinable. |

|

EP42HT-2LTE Ultra low coefficient of thermal expansion. Two component, room temperature curing epoxy. Reliable electrical insulator. Unsurpassed dimensional stability. Low linear and volumetric shrinkage upon cure. Serviceable from -60°F to +300°F. Withstands 1,000 hours 85°C/85% RH. |

|

EP30LTE-2 Thermally conductive, electrically insulative epoxy. Has low thermal expansion coefficient. Superior dimensional stability. Good flow properties. Exceptionally low shrinkage upon cure. Service operating temperature range from -100°F to +250°F. Adheres well to similar and dissimilar substrates. |

|

EP65HT Ultra fast curing two component epoxy adhesive. Rapid setup times and thermal stability. Cures quickly even in small masses. Serviceable from -60°F to +400°F. Tg is 125-130°C. NASA low outgassing certified. High tensile modulus. Superb electrical insulation properties. Vacuum compatibility. Available for use in gun dispenser. |