Master Bond offers unique adhesive systems for temporary bonding that can be removed without surface contamination. These outstanding systems have gained wide acceptance and are presently employed in the electronic, electrical, optical and metalworking industries.

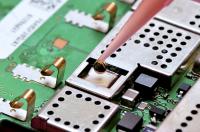

Rework procedure will vary depending on the adhesive type, bond line thickness, substrates involved, and geometry of the parts/assembly. Our products have been quite effective in replacing defective components in costly assemblies. This can be accomplished without damaging adjacent parts or sensitive substrates in an application.

In general, flexible products such as silicones & urethanes would be easier to remove as compared to rigid curing epoxies. However, achieving a smooth removal may not be easy in all applications.

Applications Featuring Master Bond Reworkable Adhesives

Master Bond’s highly regarded reworkable systems are used throughout a variety of industries. Some common applications utilizing our reworkable adhesive materials include:

- Bonding of substrates exhibiting differing CTEs

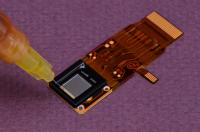

- Underfill encapsulants in the electronic packaging areas

- Encapsulation of various electronics assemblies

- Ceramic substrate attachments inside hermetically sealed packages

- Wafer bonding

- Bonding of integrated, rigid and flexible circuits

Most Popular Reworkable Adhesive Systems

|

MasterSil 151 Optically clear, addition curing potting, encapsulation, sealing compound. Low shrinkage upon cure. Resists up to +400°F [+204°C]. Shore A hardness 50-60. Highly resistant to water. Long pot life. |

|

Super Gel 9 Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F. |

|

Super Gel 9AO Thermally conductive/electrically insulative urethane modified epoxy system. Soft and resilient. Solid dimensional stability. Easily repairable. Long working life. Low exotherm. Service temperature range -100°F to +200°F. Superior electrical insulation properties. Can be cast many inches in depth. Withstands thermal cycling and mechanical shock. |

|

MB600 Environmentally safe, water soluble, one part system. Thermal stability up to +1,500°F. Outstanding strength, dimensional stability and electrical insulation properties. Completely odorless, non-toxic and non-flammable. Cures obtained at moderately elevated temperatures. |

|

UV14-3 One component, tough, flexible UV curable adhesive, sealant, coating. Fast curing. Readily removable by solvents for reworkability. Capable of withstanding rigorous thermal cycling. Serviceable from -60°F to +250°F. |