Advanced formulations feature outstanding resistance to compressive forces. Products are designed for service in structural bonding applications. Specific grades offer compressive strengths as high as 20,000-25,000 psi at room temperature.

Key Benefits of Master Bond High Compressive Strength Systems

- Corrosion resistance

- High/low temperature serviceability

- Excellent adhesion to similar and dissimilar substrates

- Easy application

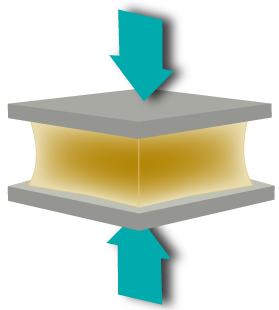

ASTM D695 test method is often employed for measuring compressive strength. Definitive strength values have enabled design engineers to reduce material costs, comply with industry standards and ensure extended life span for finished products. Our compounds have demonstrated, under uniform applied loads when placed between parallel compression plates, their capability of achieving high compressive strength properties without rupturing or deformation. Manufacturers of components, machinery, structures have been able to meet the most stringent quality control standards under variable environmental exposures such as humidity, thermal cycling. Select Master bond formulations have proven effective in maintaining their structural integrity under repetitive compressive loads at subambient/elevated temperatures. This is highlighted in their usage by leading companies in the automotive, aerospace, electronic, electrical, medical device industries.

ASTM D695 test method is often employed for measuring compressive strength. Definitive strength values have enabled design engineers to reduce material costs, comply with industry standards and ensure extended life span for finished products. Our compounds have demonstrated, under uniform applied loads when placed between parallel compression plates, their capability of achieving high compressive strength properties without rupturing or deformation. Manufacturers of components, machinery, structures have been able to meet the most stringent quality control standards under variable environmental exposures such as humidity, thermal cycling. Select Master bond formulations have proven effective in maintaining their structural integrity under repetitive compressive loads at subambient/elevated temperatures. This is highlighted in their usage by leading companies in the automotive, aerospace, electronic, electrical, medical device industries.

The chart below illustrates compressive strength values that can be achieved for select systems:

| System Type | Product | Compressive Strength, 75°F |

|---|---|---|

| Two part epoxy | EP30TC | 24,000-26,000 psi |

| Two part epoxy | EP30NS | 18,000-20,000 psi |

| Two part epoxy | EP21TCHT-1 | 22,000-24,000 psi |

| Two part epoxy | EP21SC-1 | 24,000-26,000 psi |

| Two part epoxy | Supreme 45HTQ | 22,000-24,000 psi |

| Two part epoxy | EP21AOLV-2Med | 22,000-25,000 psi |

| Two part epoxy | EP121AO | 24,000-26,000 psi |

Most Popular High Compressive Strength Compounds

|

Supreme 45HTQ Two component, toughened, quartz filled epoxy with exceptional abrasion resistance. Heat curing system. Long working life after mixing. High compressive strength. Superb dimensional stability. Serviceable from -60°F to +450°F. Withstands exposure to petrochemicals acids, bases, solvents. Good strength retention at elevated temperatures. Successfully tested for 1,000 at 85°C/85% RH. |

|

EP34 Two component, high temperature resistant epoxy adhesive, sealant, coating. Top notch electrical insulator. Dimensionally stable. Easily machinable. High strength system. Service temperature range from -60°F to +450°F. |

|

EP30QF Quartz filled epoxy system. Features high tensile modulus, outstanding compressive strength and superior dimensional stability. Good flow properties. Suitable for potting/encapsulation. Reliable electrical insulator. Low CTE. Service temperature range from -60°F to +250°F. Excellent chemical resistance. Meets NASA low outgassing specifications. Withstands 1,000 hours at 85°C/85% RH. |

|

EP21AO Room temperature curing thermally conductive/electrically insulative epoxy adhesive. Convenient one to one mix ratio, weight or volume. High bond strength. Adheres well to metals, composite, ceramics, glass, rubbers and most plastics. Superb dimensional stability. Serviceable from -60°F to +250°F. |

|

EP30LTE-LO Two component epoxy system. Extra low thermal expansion coefficient and unmatched dimensional stability. Bonding, sealing, casting compound. Passes NASA low outgassing specifications. Room temperature curing. Low shrinkage. Serviceable from 4k to +250°F. Successfully tested for 1,000 hours 85°C/85% RH. |

|

Supreme 12AOHT-LO One component, heat cure system for bonding, sealing. High strength product. Service operating temperature range from 4K to +500°F (260°C). Resists aggressive thermal cycling and shock. Substantial thermal conductivity of 9-10 BTU in/ft2 hr °F. Smooth thixotropic paste. NASA low outgassing approved. Meets MIL-STD-883J Section 3.5.2 for thermal stability. Withstands 1,000 hours 85°C/85% RH. |

|

EP21TDCAOHT Flexibilized two component epoxy offers thermal conductivity/electrical insulative properties. High peel/shear strength formulation. Paste viscosity. Will not drip on vertical surfaces. Bonds well to dissimilar substrates. Serviceable from -100°F to +350°F. |