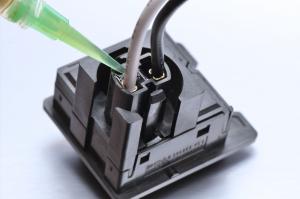

Electrical arcing is a luminous discharge of current that is formed when a strong current jumps a gap in a circuit or between two electrodes. Arcing can arise through a number of occurrences, including breaks in the electrical insulation, corrosion, faulty insulation, exposed surfaces on the conductor, rupturing, among others. This causes the electrical current to lose its way and travel through the tainted insulation, jumping from one conductor to the other. The conduction is not controlled and the air surrounding the current is ionized and arcs, which may lead to combustion and fire. It is therefore critical to either avoid the condition entirely, or if arcing does occur, to limit the damaging repercussions.

An electric arc can potentially cause degradation of plastics. Compounds can be specifically formulated in a way that makes them not susceptible to such degradation. Underwriters Laboratories (UL) developed comprehensive standards to evaluate these materials, including UL 94HB flame retardancy rating for 1.5 mm and 3 mm thickness. High Amp Arc Ignition (HAI) specification per UL 746A tests materials for resistance to over 150 arcs without igniting.

UL Certified Arc Resistant Epoxy

Master Bond EP21AC passed UL 746A High Amp Arc Ignition test with the highest rating, which is a Performance Level Category or PLC of 0. This epoxy compound, when cured at a thickness of 3.0 mm, withstood over 150 arcs without ignition. It also passed the UL 94HB flammability test.

Master Bond EP21AC passed UL 746A High Amp Arc Ignition test with the highest rating, which is a Performance Level Category or PLC of 0. This epoxy compound, when cured at a thickness of 3.0 mm, withstood over 150 arcs without ignition. It also passed the UL 94HB flammability test.