Expanded Product List

Master Bond Product Search

630 products match

|

Supreme 45HTND-2LO Black Toughened, two component, non-drip epoxy paste. Service temperature range -100°F to +450°F. Long working life. Gap filling. Meets NASA low outgassing specifications. Withstands 1,000 hours 85°C/85% RH. Superior electrical insulator. Heat curing. |

|

Supreme 45HTQ Two component, toughened, quartz filled epoxy with exceptional abrasion resistance. Heat curing system. Long working life after mixing. High compressive strength. Superb dimensional stability. Serviceable from -60°F to +450°F. Withstands exposure to petrochemicals acids, bases, solvents. Good strength retention at elevated temperatures. Successfully tested for 1,000 at 85°C/85% RH. |

|

Supreme 45HTQ-4 Toughened, two component silicon carbide filled epoxy. Heat curable. Exceptional abrasion and chemical resistance. Serviceable from -100°F to +450°F. Can withstand high compressive loads and rigorous thermal cycling. Good strength retention at elevated temperatures. |

|

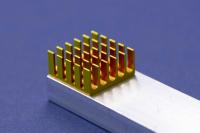

Supreme 46HT-1AO Toughened epoxy system, resists thermal cycling. Serviceable from -100°F to +500°F. Exceptionally long working life. Thermally conductive, electrically insulative. |

|

Supreme 46HT-2 High strength epoxy adhesive. Outstanding toughness and durability. Serviceable from -100°F to +500°F. Withstand mechanical shocks and rigorous thermal cycling. Excellent peel strength. Cures at elevated temperature. |

|

Supreme 46HT-2ND2 Two component, non-drip, toughened, heat resistant epoxy adhesive. Superior durability and bond strength. Withstands chemical exposure. Paste consistency. Gap filling. Serviceable from -100°F to +500°F. Successfully tested for 1,000 hours 85°C/85% RH. Outstanding thermal cycling capabilities. |

|

Supreme 46HTQ Quartz filled epoxy system for bonding, sealing, casting. Service temperature range -80°F to +500°F. Superior chemical and abrasion resistance. Dimensional stability. High compressive strength. Good strength retention at elevated temperatures. Oven curing compound. |

|

Supreme 62-1 Cures rapidly at moderate elevated temperatures. Superior resistance to moisture. Two part epoxy has long pot life at ambient temperatures. High bond strength properties. Reliable electrical insulator. Serviceable from -60°F to +450°F. Withstands aggressive chemical exposure. Tg 160-165°C. Shore D hardnes >80. Excellent toughness. |

|

Supreme 65HT-6 Fast room temperature curing heat resistant epoxy adhesive. Serviceable from -80°F to +400°F. Sets up in 5-10 minutes at room temperatures. High tensile lap shear strength. Superior dimensional stability. Good chemical resistance. Tough bonds. Ability to withstand impact and thermal cycling. |

|

Supreme 70CN Two component, toughened epoxy system for bonding, sealing, coating and potting derived from natural substances. Low shrinkage upon curing. Exceptional wetting properties. Service temperature range is -100°F to +450°F. |