Two component epoxy for structural bonding featuring superlative heat resistance; requires oven curing

Key Features

- Glass transition temperature over 240°C

- Impressive chemical resistance

- Outstanding electrical insulation properties

- Long pot life at room temperature

- Service temperature range of -100°F to +600°F

- High bonding strength

Product Description

Master Bond EP46CA is a two part epoxy system for high performance structural bonding and sealing, suitable for applications where resistance to temperatures from -100°F to +600°F is required. It is 100% reactive and does not contain any solvents or diluents. While it does not cure at room temperature, it does cure readily at elevated temperatures. A good curing schedule to optimize properties is 2 hours at 300°F, followed by a few hours at 350-400°F. The cured epoxy produces bonds and seals with high mechanical strength and excellent chemical resistance. EP46CA has a forgiving 100 to 35 mix ratio by weight. It should be noted that EP46CA is relatively exothermic and should not be cured in sections greater than 10-20 thousandths of an inch thick and a bondline thickness is typically 2-6 thousandths of an inch.

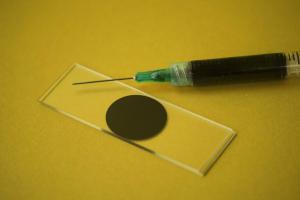

Although EP46CA is primarily used for structural bonding, it is also a superb choice as a matrix resin for fiber reinforced, high performance, heat resistant composite structures. It can withstand intense thermal cycling and resist many chemicals, including water, oils, solvents, bases and acids. It bonds exceptionally well to metals, composites, glass, ceramics and many plastics. Once cured, the system is a top tier electrical insulator. The color of Part A is black and Part B is moderately dark brown. EP46CA is normally used in demanding applications found in the aerospace, electronic and specialty OEM industries where exceptional thermal and chemical resistance might be required.

Product Advantages

- Easy application: contact pressure only required for cure, system spreads evenly and smoothly

- Convenient cure schedules at elevated temperatures

- Outstanding heat resistance and thermal stability

- Robust chemical resistance

- First rate electrical insulation properties even upon prolonged exposure to hostile environments

- Working life over 24 hours at room temperature

Packaging

EP46CA is available is various sizes and units to accommodate customer's needs.