Expanded Product List

Master Bond Product Search

442 products match

|

EP42HT-2HV1 Chemical resistant, two component, room temperature curable epoxy. Serviceability from -60°F to +450°F. Withstands exposure acids, alkalis, solvents, sterilants such as radiation, steam, EtO. Post curing is recommended to optimize properties. Castable to thicknesses exceeding 2-3 inches. |

|

EP42HT-2LO NASA low outgassing approved epoxy for service from -60°F to 450°F. Cures at ambient temperatures. Tensile strength >12,000 psi. Shore D hardness 80-90. Superior dimensional stability. Remarkable chemical resistance. Withstands 1,000 hours 85°C/85% RH. Castable in thicknesses exceeding 2-3 inches. Vacuum compatible. |

|

EP42HT-2LTE Ultra low coefficient of thermal expansion. Two component, room temperature curing epoxy. Reliable electrical insulator. Unsurpassed dimensional stability. Low linear and volumetric shrinkage upon cure. Serviceable from -60°F to +300°F. Withstands 1,000 hours 85°C/85% RH. |

|

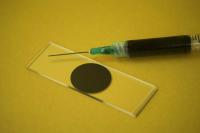

EP42HT-2Med Black USP Class VI approved. Serviceable from -60°F to 450°F. Withstands multiple cycles of medical sterilization including radiation, EtO, autoclaving and chemical sterilants. Shore D hardnes >75. Used for bonding, sealing, coating, casting. Can be cured up to 2-3 inches thick. Cures at ambient temperature or more quickly at elevated temperatures. |

|

EP42HT-2Med Low viscosity, two part epoxy with outstanding chemical resistance. Passes USP Class VI biocompatibility tests. Capable of withstanding repeated sterilization cycles including radiation, EtO, chemical sterilants, autoclaving. Serviceable from -60°F to +450°F. Cures at room or elevated temperatures. Available in amber-clear and black colors. Castable in thicknesses up to 2-3 inches. |

|

EP42HT-2ND-2 Serviceable from -60°F to 450°F. Cures at ambient temperatures, or faster with heat. Tensile strength 10,000-11,000 psi. Shore D hardness 80-90. Superior dimensional stability. Remarkable chemical resistance. |

|

EP42HT-2ND-2Med Black Two component epoxy paste adhesive. Resists sterilization exposure. USP Class VI approved. Outstanding thermal stability and electrical insulation properties. Cures at ambient temperatures. Withstands multiple cycles of autoclaving, radiation, EtO and chemical sterilants. Post curing is recommended to optimize physical properties. Serviceable from -60°F to +450°F. |

|

EP45HT High performance adhesive/sealant/coating. Serviceable from -80°F to +500°F. Resists thermal cycling. Outstanding resistance to acids, bases, petrochemicals, water. 100% reactive. Cures at elevated temperatures. Good flow properties. Moderate viscosity. Excellent performance profile for long term exposures at 400°F to 450°F. Well suited for moderate sized electronic potting applications. |

|

EP45HTMed USP Class VI certified. Withstands repeated cycles of sterilization such as autoclaving, radiation and chemical sterilants. High bond strength. Heat curing. Two component epoxy system. Long pot life. Service operating temperature range from -80°F to +500°F. |

|

EP46CA Oven curing. Two component epoxy for bonding/sealing. Long pot life. Serviceable from -100°F to +600°F. T > 240°C. High bond strength. Outstanding electrical insulation properties. Robust chemical resistance. |